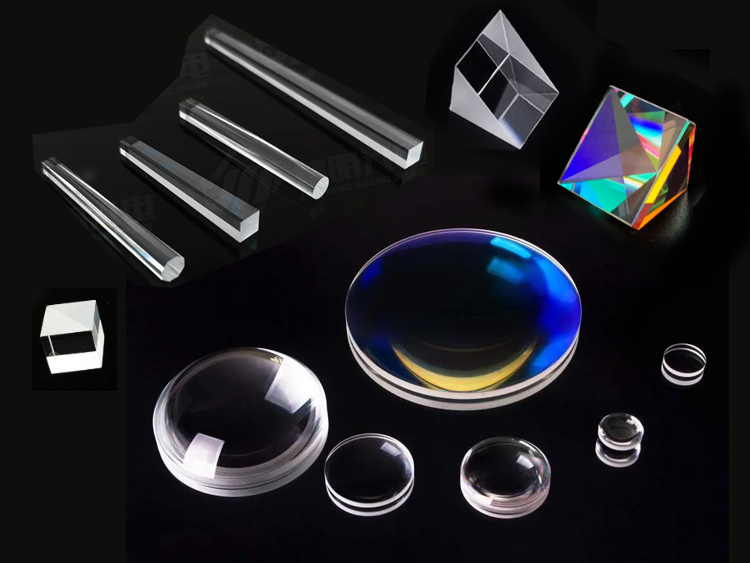

Optical glass, also known as optical lenses or glass lenses, is typically categorized as plano-convex (PCX), double-convex (DCX), plano-concave (PCV), or double-concave (DCV) lenses. They are commonly made from materials such as soda-lime, borosilicate, and quartz, with diameters varying from 1mm to 300mm and tolerances held to within ±0.1mm. Distinguished by their scratch resistance, these lenses are easy to clean and maintain due to their polished, smooth surfaces that resist oil and chemical contamination. Notably, quartz glass lenses boast a high light transmittance rate of up to 95%. These lenses are essential in various domains including daily life, science, education, and industry, being integral components in lights, cameras, microscopes, telescopes, and collimators, among others.

Advantages:

Chemical Stability and Easy Maintenance: The glass material’s anti-corrosion properties make it easy to clean and maintain.

Precise Tolerance: With over a decade of experience in optical glass manufacturing, we can tailor tolerances to meet your needs, even achieving minimal values for high-precision applications.

Surface Covering: Our surface coverings assist in anti-reflection and filtering.

Applications:

Magnification: Convex lenses serve as magnifying glasses, aiding in the observation of minuscule objects.

Education: Optical lenses play a significant role in physics and are widely used in schools for educational purposes.

Instrumentation: Medical, biological, and astronomical instruments such as microscopes, telescopes, and collimators frequently employ optical lenses.

Photography: Glass lenses are integral to the imaging process in cameras.

Lighting: Optical glass aids in light manipulation, concentrating or scattering rays for specific purposes.

Specifications:

Classification: Optical lenses are categorized as plano-convex (PCX), double-convex (DCX), plano-concave (PCV), or double-concave (DCV).

Material: These lenses are made from soda-lime, borosilicate, or quartz.

Diameter: Ranges from 1-300 mm.

Diameter Tolerance: Maintained within ±0.1 mm.

Thickness Tolerance: Controlled within ±0.1 mm.

Curvature Radius Tolerance: Usually ±0.5, but can reach ±0.1% in precision applications.

Centration: Less than 3 minutes of arc.

Clear Aperture: Over 90%.

Beveling: Below 0.2 × 45° or as per requirements.

Refractive Index: Between 1.4 and 1.6.