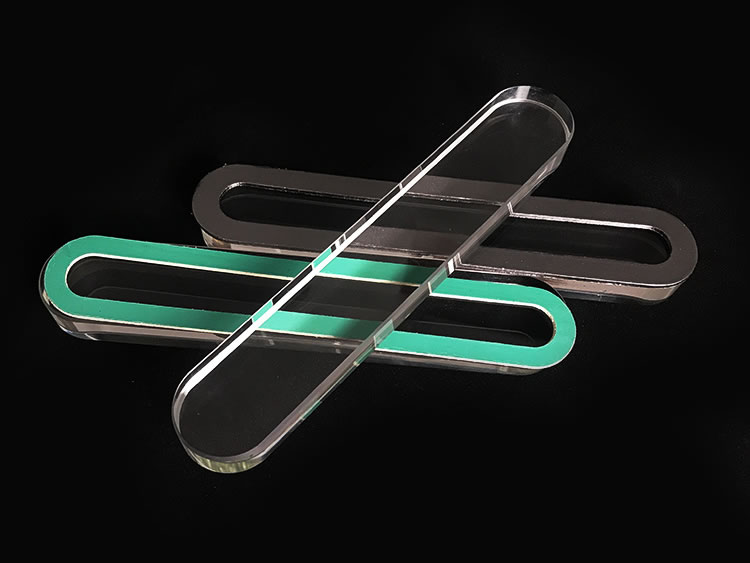

Transparent flat gauge glass, also called transparent sight glass, transparent level glass and transparent level gauge, is usually made of borosilicate glass and aluminosilicate glass. The glass is manufactured into the strip shape and used in boiler or some instruments for observing the liquid level.

Reflex Gauge Glass, designed with a prismatic surface facing the liquid in a tank or boiler, enhances visibility, ideal for low to medium pressure applications. In contrast, Transparent Level Glass, a fully transparent material, allows for direct observation of the liquid, useful for color-indicating substances or applications requiring inspection of liquid characteristics. Though suitable for high-pressure applications, it tends to be more expensive and may need more maintenance due to occasional mica shield replacements.

Transparent Flat Gauge Glass Used in Industry Pipe

Plain Transparent Gauge Glass

DIN 7081 Transparent Borosilicate Gauge Glass

Transparent Flat Level Gauge Glass

1,Materials

Our Transparent Gauge Glasses are composed of two high-grade materials – borosilicate glass and aluminosilicate glass. Borosilicate glass, renowned for its outstanding resistance to heat and chemical corrosion, ensures a high degree of durability for our products. Meanwhile, Aluminosilicate glass adds to the toughness and scratch resistance of our gauge glasses, making them well-suited for demanding industrial applications.

One key feature of our Transparent Gauge Glasses is the excellent transparency offered by both borosilicate and aluminosilicate glasses. This ensures that the liquid level can be observed clearly without any distortion, irrespective of the lighting conditions or the nature of the liquid being measured.

2,Features

Our Transparent Gauge Glasses are manufactured in a strip shape, which makes them ideal for use in boilers and similar instruments where observing the liquid level is crucial. This unique design not only provides a clear view of fluid levels but also enhances the overall usability and functionality of the equipment they are installed in.

3,Surface Treatment

We take great care in the surface treatment of our Transparent Gauge Glasses. First method is as same with reflex Gauge Glasses, both sides of the glass are ground and polished to ensure optimal transparency, allowing for the accurate monitoring of fluid levels. The second method,we use a high borosilicate sheet of 17mm thickness, which is then cut according to the required size. The side face of the glass sheet is polished to achieve a smooth finish, preventing any risk of injury during installation or operation.

4,Manufacturing Process

Our Transparent Gauge Glasses are created using two primary manufacturing techniques:

Mold-Based Manufacturing: Similar to the process used for reflex Gauge Glasses, we employ molds to create semi-finished products. After the initial shaping, we undertake careful grinding and polishing on both sides of the glass to ensure optimal transparency. While this method offers a straightforward manufacturing process, it may result in slightly less precise visual clarity compared to our second method.

Sheet-Based Manufacturing: The second technique involves using a High Borosilicate sheet of 17mm thickness. Each glass sheet is precisely cut according to the required dimensions, and the side face is polished for a smooth finish. This technique delivers superior clarity and transparency, making it ideal for applications where precision viewing is crucial. However, due to the specialized materials and processes used, the cost for products produced by this method is relatively higher.

Regardless of the manufacturing technique used, all our Transparent Gauge Glasses are produced according to DIN7081 and DIN7080 standards. These stringent standards ensure that our products consistently meet the high levels of quality and performance that our customers expect from us.

5,Applications

Our Transparent Gauge Glasses find their applications in various industrial scenarios, offering reliable performance, superior visibility, and long-lasting durability.

Industry Pipe Usage: Our Flat Transparent Gauge Glass is widely used in industry pipes, where it provides clear visibility for liquid flow and levels. This application helps in monitoring the fluid’s behavior, ensuring smooth operation and avoiding potential problems that might occur due to changes in fluid levels.

Borosilicate Transparent Flat Gauge Glass: With excellent thermal resistance and chemical stability, our borosilicate transparent flat gauge glasses are well suited for applications involving high temperatures or corrosive fluids. This can include laboratory equipment, chemical processing units, and industrial boilers.

Aluminosilicate Transparent Gauge Glass: Aluminosilicate transparent gauge glass, with its superior hardness and scratch resistance, is commonly used in environments where the glass may be exposed to physical impact or abrasive substances. This can include heavy industry machinery, or oil and gas applications.

6,Technical Information

1)Transparent Flat Gauge Glass:

Our Transparent Flat Gauge Glass is manufactured from “extra-hard” borosilicate glass. This superior material provides excellent thermal and chemical resistance, making our gauge glass exceptionally durable and well-suited to high-temperature and chemically-intensive environments. The “extra-hard” borosilicate glass ensures that our products maintain their form and function even under harsh conditions, providing accurate and reliable readings at all times.

Material: borosilicate glass,manufactured from “extra-hard” borosilicate glass.Borosilicate glass is a type of glass that includes at least 5% boric oxide.

Transmissivity (Visible light transmission): Borosilicate glass typically has a very high light transmission, often above 90%.

Shock temperature (Thermal shock resistance): The thermal shock resistance of borosilicate glass is very high, often up to 160°C or more.

Softening temperature: The softening temperature, or the temperature at which the glass becomes malleable, is typically around 820°C for borosilicate glass.

Bending strength: The bending strength of borosilicate glass is around 69 MPa (megapascals).

Working temperature: The maximum working temperature of borosilicate glass is usually around 450°C, although it can vary depending on the specific formulation.

Working pressure: The working pressure can vary greatly depending on the thickness and shape of the glass, as well as the specific application. Generally, borosilicate glass can withstand high pressures, often up to several tens of bar.

2)Aluminosilicate Transparent gauge glass

Our aluminosilicate glass is the epitome of clarity and robustness. As a material of choice for our gauge glasses, aluminosilicate glass offers superior hardness and scratch resistance. This makes it particularly suitable for environments where physical impact or abrasive substances are present. The crystal-clear transparency of aluminosilicate glass ensures perfect visibility for accurate monitoring and measurement of liquid levels.

Material: aluminosilicate glass.

Form: strip.

Transmissivity: 91.8%

Shock temperature: ≤ 370 °C

Softening temperature: ≥ 920 °C

Bending strength: 180–220 MPa

Working temperature: 600 °C

Working pressure: 200 MPa

Technical Notes:

1.The thickness of the various non-standard aluminosilicate glass can be customized.

2.Other sizes can be customized.

1).The thickness of the various non-standard aluminosilicate glass can be customized.

2).Other sizes can be customized.

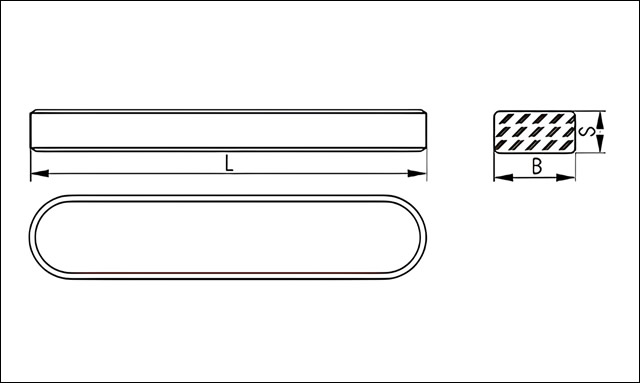

| Size | Type A | ||

| Length | Width | Thickness | |

| 0 | 95 | 30 | 17 |

| I | 115 | 30 | 17 |

| II | 140 | 30 | 17 |

| III | 165 | 30 | 17 |

| IV | 190 | 30 | 17 |

| V | 220 | 30 | 17 |

| VI | 250 | 30 | 17 |

| VII | 280 | 30 | 17 |

| VIII | 320 | 30 | 17 |

| IX | 340 | 30 | 17 |

| Size | Type B | ||

| L | B | S | |

| 0 | 95 | 34 | 17 |

| I | 115 | 34 | 17 |

| II | 140 | 34 | 17 |

| III | 165 | 34 | 17 |

| IV | 190 | 34 | 17 |

| V | 220 | 34 | 17 |

| VI | 250 | 34 | 17 |

| VII | 280 | 34 | 17 |

| 300 | 34 | 17 | |

| VIII | 320 | 34 | 17 |

| IX | 340 | 34 | 17 |

| X | 370 | 34 | 17 |

| XI | 400 | 34 | 17 |

| XII | 420 | 34 | 17 |

The sizes are all customized according to clients’ requests.

7,Advantages of Transparent Gauge Glass

1)Optimal Transparency: The finely smooth surfaces on both sides of our Transparent Gauge Glasses ensure optimal transparency. This feature provides a clear and undistorted view of the fluid levels, enabling accurate readings and efficient operations.

2)High Transmittance and Environment Resistance: Our Aluminosilicate Transparent Gauge Glasses are known for their high transmittance and resistance to aggressive environments. This makes our transparent sight glass an ideal choice for industrial and petrochemical applications, where they can withstand harsh conditions without losing their clarity or performance.

3)Versatility in Service Conditions: The robustness of our Transparent Gauge Glasses allows them to be used with all media at service conditions up to 200MPa and temperatures up to 430 degrees centigrade. This flexibility means that our products can be used in a wide range of environments, from low to high pressure, and in extreme temperature scenarios, while still maintaining precise and reliable readings.